For port matching your intake and heads, you can find your ideal intake manifold gasket to use as a template. Holley Performance/Mr Gasket offers this port gauge I use with 28 popular port sizes for small- and big-block Chevy heads. The hard plastic material makes scribing your heads easier. The Tools Basic head-porting tools will not break the. Cylinder Head Porting Secrets Dodge 360 LA Engine Templates Buy Edelbrock Top End kits 1967 – 1991 Small Block Chrysler Small Block Mopar Rockers Edelbrock LA 360 Dodge Engine.

Selecting the best cylinder head for your application takes careful consideration and requires weighing many factors so you have the correct casting that matches your engine package. Heads flow air and manage the combustion of the fuel charge and, therefore, are critical for attaining the proper output level. You need to have your application and performance targets clearly defined so you end up with the correct head.

This Tech Tip is From the Full Book, HOW TO BUILD SUPERCHARGED & TURBOCHARGED SMALL-BLOCK FORDS. For a comprehensive guide on this entire subject you can visit this link:

LEARN MORE ABOUT THIS BOOK HERE

SHARE THIS ARTICLE: Please feel free to share this article on Facebook, in Forums, or with any Clubs you participate in. You can copy and paste this link to share: https://mopardiy.com/how-to-build-mopar-engines-for-performance-cylinder-heads/

In the following sections, I cover most of the original production and the performance heads, but I focus on currently available heads. In the early 2000s, Chrysler/Mopar offered more than 30 different heads for the Mopar small-block engine, and this number does not include any actual current production heads. The aftermarket offers many more performance heads, which I also cover.

The head must work with all other engine components for the engine to be successful. The short block’s displacement, the compression ratio, the intake manifold, throttle body/ carb induction system, camshaft, and valvetrain all play important parts for the team that makes the final output of torque/power. If the short block is not up-to-snuff, the best heads can’t deliver the desired power. No air flows through the ports in the head unless the valves open (and the cam opens the valves), so the cam is a very important part of the airflow team, even though it doesn’t flow air.

Once you define your application and what you expect from the engine, you can select a set of heads to best suit this application. Prepping the heads properly and matching the rest of the engine parts to this head are the key factors to making high torque and power outputs.

Identification

Looking at the casting number is the most reliable method to identify a head. Typically this number is located on the top of the cylinder head but inside the valvecover gasket area, which means that you can’t observe it if the valvecover is installed.

So the first tip is that the A-engine uses a 5-bolt attaching pattern and the Magnum engines use a 10-bolt attaching pattern. The next tip is that A-engines use a 7-digit casting number and Magnum engines use an 8-digit casting number.

Some performance (non- production) and aftermarket heads are aluminum or cast iron and have unique casting numbers or other logos to identify them. Notice that the specifications are very similar among production-based heads, but the best spec is the intake valve head diameter, which is 1.92 for the Magnum and 1.75, 1.88, or 2.02 for various A-engines.

It is very easy to install large valves if the cylinder head is rebuilt, so using the actual valve’s head diameter to determine which version of a head that you have is flawed.

Production Cylinder Heads

Most production LA-engines are more than 40 years old, so the key is having one set of heads in good shape to use in a performance engine.

When building a max- performance small-block of 500 hp or more, one of the latest aftermarket cylinder heads produces much more performance than many of the cast-iron OEM heads. Cast-iron or aluminum Indy heads are an excellent choice. Although production heads can be ported and modified to accept modern valvetrains, you’re going to save time and money by starting with a current aluminum aftermarket model.

340

The 340 head provided exceptional performance and was highly desired and sought after for the A-engine. These heads are referred to as “915” heads because the last three digits of the casting number are 915. But they are also called “X” and “J” heads based on the cast letter on the head in addition to the casting number (versions of the 894 head).

These were good heads in 1968, but there are better castings in the production head lineup. The 308 head is regarded as the best A-engine casting, and it was in production from about 1988 through 1992, but it was not an exclusive casting.

Another aspect of these production heads is that the 1981–1987 318 4-barrel engines used 360 heads as part of the E48 high-performance 4-barrel or police option. After 1971, all high-performance production 340/360 heads had a 1.88 intake valve, which can easily be upgraded to a 2.02-inch intake valve for max-performance applications.

308/576

The 308 head is the best production cylinder head, and it uses a copy of the W2 exhaust port (perhaps the best-flowing exhaust port in any small-block head). It just flows more air. The roof of the intake is raised. With matching valve size, it makes more power.

Introduced in the late 1980s the 308 was one of three 360 castings that were installed on trucks from 1988 to 1992, so it is difficult to find in the typical junkyard. Mopar Performance began selling these 308 heads around 1990 as a service for Mopar Stock and Super Stock racers.

Although A-engine production stopped in 1992, dealers often were lucky to get them when ordering service heads. Then Mopar Performance sold the 308 castings machined as 360 production heads with 1.88-inch intake valves, and eventually a 340 version with 2.02 valves was offered.

Later, the casting number changed to “576” (the last three digits). It had the same ports as the 308 and they flowed the same; only the casting number changed. Both heads had the same open combustion chamber as the other 340/360 heads and the same 1.88/1.60 valve sizes. Mopar Performance created an offset pushrod version to duplicate the 340 T/A heads, but it wasn’t very popular. The 308/576 cast-iron head was quite popular for about 10 years when production stopped.

W Head

The “W” series of small-block heads are high-performance heads. The W2 was introduced in the early 1970s. It was probably the best cast-iron small-block head for 40 years. The W2 has a casting number of 3870810, and the large, oval intake ports easily identify it. The W2 was offered as an economy version with cast pedestals; the race version had offset rocker shaft stands.

The second-generation W2 was introduced in 1989–1990. The third-generation W2 was unveiled in 1998 and is visually different from the first two versions. Two large external ribs were added to each end of the head on the exhaust side and smaller ribs were added on each side of the short head bolts (exhaust side).

A closed-chamber version was added at this time, along with the capability to be used with the new 48-degree tappet blocks. This last version is a machining change and not a unique casting. By the early 2000s, Mopar Performance offered 10 different W2 heads.

Introduced in 1988, the W5 is an aluminum head that weighs about 25 pounds, but it is no longer available. The aluminum W7 was introduced a couple of years later. It had large ports and flowed a lot of air but was the last head designed before CNC-porting became readily available.

The aluminum W8 was introduced in 1998 and was only used in the NASCAR Craftsman Truck series and the NHRA Pro Stock Truck series. It weighs 35 pounds and was designed for CNC-porting. It also uses 15-degree valve angles rather than the standard 18 degrees. The W9 head was introduced in 1999. It weighs about 22 pounds, or 20 if it is ported. It was also designed for CNC-porting but some versions were designed for use without porting; it flowed 290 cfm out of the box.

Magnum

Released in 1992 on the 5.2L engine, Magnum heads use a “bathtub-shape” closed-style chamber rather than an open chamber. The Magnum chamber is smaller in volume than the A-engine chamber (60 versus 70 cc). It also uses a 1.92-inch intake valve and a 1.625-inch exhaust valve, which is larger than the production 360 but smaller than the 1968–1971 340. The stock Magnum’s intake port flows slightly better than the 360 A-engine’s intake port (190 versus 170 cfm), which may be due to the larger valve.

Another unique feature of Magnum heads is that there is no heat crossover in the center of the intake face. Because it is fuel injected, it does not need the heat in the intake manifold for driveability advantages. Magnum heads have 10 valvecover attaching screws and 8 rocker stands, one for each valve.

R/T

The cast-iron high-performance R/T head was designed for the Magnum engine as a direct replacement, and it’s essentially a Magnum engine W2 head. It flows more air than the standard head (229 versus 190 cfm) and has larger intake ports (180- versus 153-cc intake) using the same valve size. It has the “R/T” logo and the “Mopar” logo cast into the exhaust face between the short head bolts.

T/A

The 340 Trans-Am engine was produced with special cast-iron cylinder heads based on the “915” casting (3418915 casting number). The 915 was going to be the 360 production head in 1971 and the 1972–1973 340 head, and was specially machined for the T/A program.

The main differences were the use of the larger intake valve (2.02 inches), and the intake pushrod hole (machined) was moved away from the intake port. The actual as-cast ports were the same as the standard 915 heads. The moved pushrod required offset rocker arms (mechanical or adjustable) on all the intake valves.

Commando

The aluminum Commando head for A-engines was introduced in 2001. It was designed to be a “street” aluminum head, so it was interchangeable with the standard 340 heads. The intake ports were larger than stock cast-iron heads at 177 cc, and flowed better than stock cast-iron heads, at 222 cfm. These heads could be used with the standard stamped rocker arms. There was also a large-port, Super Commando aluminum-head version that required offset intake rockers.

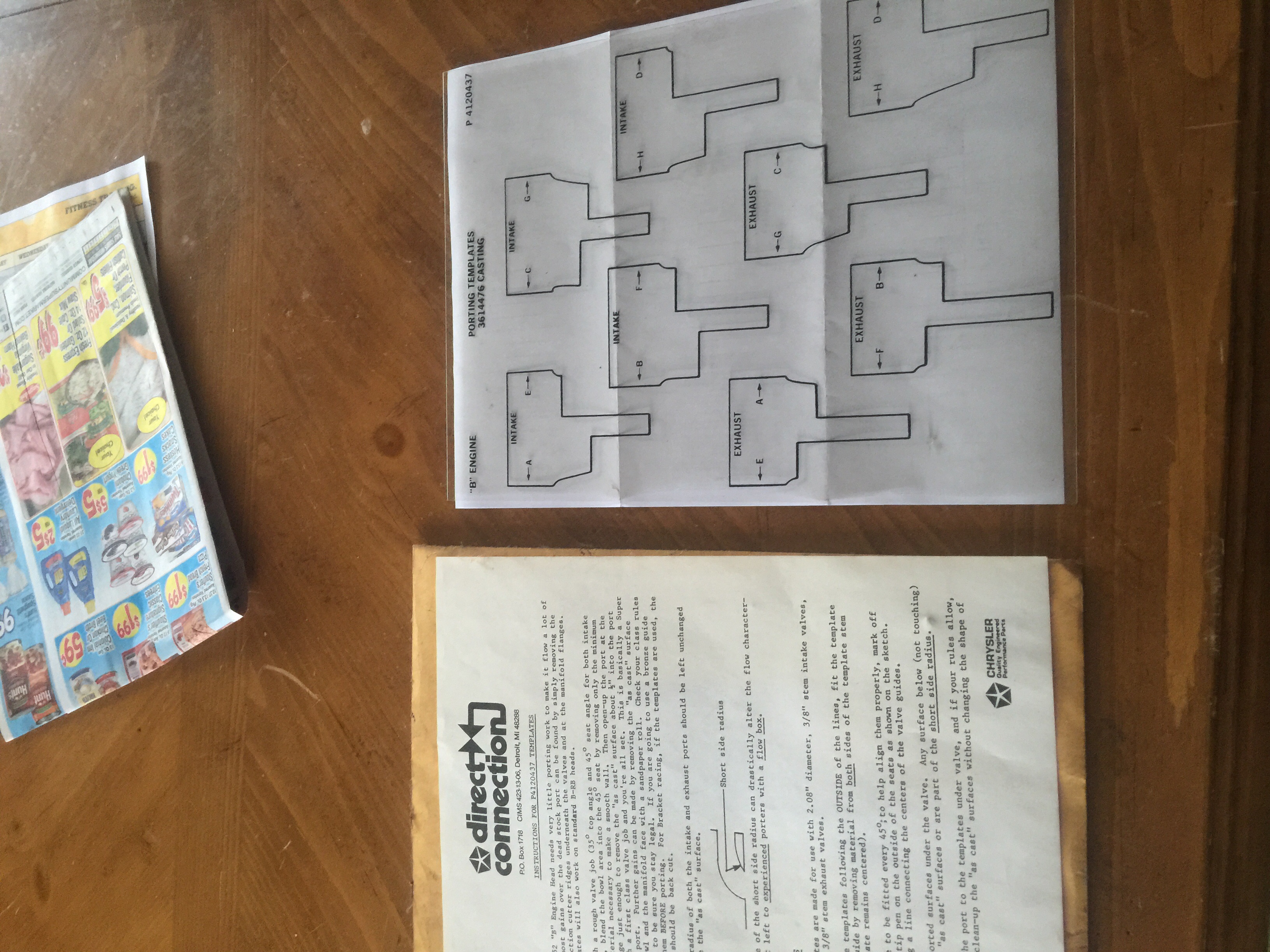

Mopar Head Porting Template

Aluminum Magnum

Designed for “street” use, the aluminum Magnum head was introduced in 2000. It was interchangeable with stock cast-iron Magnum heads. The intake ports were larger than the stock cast-iron heads (at 177 cc) and they flowed more air (at 222 cfm). With any of the 360 and 1972– 1973 340 cast-iron heads, you should always upgrade the 1.88-inch intake valve to the 2.02-inch valve.

Head Spec Comparison

Many specifications relate to a cylinder head, and they can be used to compare one head to another. Many people focus on flow numbers, and most often the peak flow on the intake port, while exhaust is rarely considered.

A flow bench generates a curve of port flow according to valve lift, and the peak flow is at the peak valve lift. Valve lift is often disregarded, but it’s important. When comparing different heads, make sure the valve lift is the same and then look at the flow numbers so the comparison is valid.

For example, let’s assume that you are building a street/strip engine and have selected a .500-inch-lift cam. One head flow 280 cfm at .500-inch lift and another flow 300 cfm at .700-inch valve lift. The key is to look at the flow at .500 lift. The 300 cfm head may be 250 or 260 cfm at .500 lift, and there

fore the 280 cfm head becomes the better choice. Another thing that makes comparisons difficult is valve size. The 280-cfm head might have a 2.020-inch intake valve and the 300-cfm head might have a 2.100-inch.

Bigger ports are not always better and, in fact, ports need to be correctly sized to the engine package. Ports are usually sized by volume (in cubic centimeters). The typical 360 port is 166 cc and the ported W9 aluminum head was in the range of 260 to 270 cc. The W9 tends to be fl owed at high lifts, such as .700 to .800 inch, and the 360 is fl owed at lower lifts such as .500 to .600 inch. With differences such as these, the first measurement needs to be taken at your cam’s max valve lift. In our example, it’s .500 inch. If that is close, determine flow at half lift, which is .250 inch in the example. Usually the flow curve shows the flow at .200 and .300 inch, so pick one and check the flow at that point.

The higher fl ow at the .200/.300-inch point is the better head for your application if they were tied at .500 lift. The valve and the valve job also affect the airflow capability. It’s also important where the valve sits in the chamber (don’t sink the valve) and how the air enters the chamber at low lifts (chamber reliefs). The valve job angle and the shape of the underside of the valve head are also important to the airflow numbers.

Aluminum Heads

Most aluminum heads use larger port volumes than the similar cast-iron heads. During the cast-iron head drought, the aluminum heads were the only choice. Aluminum castings lend themselves to low-volume production, so these may be made in batch runs of 100, 500, and 1,000. This makes them popular with the aftermarket for racing applications, which spills over into many other performance uses.

The aftermarket built the first aluminum cylinder heads for the Mopar A and Magnum small-blocks. Chrysler made the only cast-iron service heads for the A-engine small-blocks and they were kept in stock for 10 years or so. Mopar Performance had provided heads for most engines.

Between 2000 and 2010, all this changed and most Mopar heads were no longer available. In the past couple of years, this has changed again; there are now several versions of aluminum heads.

The three aluminum heads from Edelbrock, Indy Heads, and B1-BA all flow about 260 cfm in stock configuration. That means that economics should decide your selection. These heads are also offered in ported form where the Indy Heads version (339) and the Brodix B1-BA version (340) are equal, so economics can again be used to select between these two heads. The latest data indictes that the newest B1-BA CNC-ported head by Koffel’s Place makes more than 360 cfm, which makes it the best-ported small-block head to date!

Edelbrock Aluminum Heads

Edelbrock offers several aluminum heads for A-engines (five valvecover screws). The 1968–1971 340 “A” head features a larger, open combustion chamber. It provides clearance for the piston because it sits above the deck at TDC. With all other A-engines (including 318s, 1972–1973 340, and all 360s), the pistons sit below the top of the block, so this special feature is not required.

The aluminum A-engine head has chamber volumes of 63 and 65 cc, intake port volume of 171 cc, and valve diameters of 2.02-inch intake and 1.60-inch exhaust. These dimensions are the same as for the 1968– 1971 340.

Edelbrock carries aluminum heads for Magnum engines. These heads have chamber volumes of 58 cc, intake port volume of 176 cc, and valve diameters of 2.02-inch intake and 1.60-inch exhaust. Although these dimensions are the same as the 1968–1971 340, the heads are different from the production Magnum. Edelbrock also offers aluminum heads for use with hydraulic cams and hydraulic roller cams. Similar to the A-engine, heavier valvesprings are used for a hydraulic roller that has higher-load springs. These heads also use 11/32-inch valvestem diameters and manganese-bronze valveguides. They use 14-mm x 3/4-inch–reach spark plugs (recommended Champion RC12YC or equivalent). The valvespring installed height is 1.800 inches.

ARP lists the same head bolts for the Edelbrock Magnum heads as for the production version, which means five extra-long head bolts. Caution: The specs indicate that these heads use 3/8-inch rocker studs, which may mean that you need larger bolts or must change the valve gear. Both Edelbrock aluminum heads (A-Engine and Magnum) flow the same 260-cfm intake at .600-inch lift and 251 cfm at .500-inch lift. Both are very good numbers. Edelbrock aluminum heads flow excellent out-of-the-box, and lead the affordability list at most shops. It is a great bolt-on head. At this time, Edelbrock does not list ported upgrades.

Caution: ARP lists the same head bolts for Edelbrock heads as for the W2, which means two extra-long head bolts (a typical 340 or 360 has five long and no extra-long). Edelbrock also has an aluminum head for race only, which features a 58-cc chamber and a larger 225-cc intake port. The ports are fully CNC-ported and use 16-degree valve angles. Flow numbers were not published.

Aluminum Indy Heads

The Indy Heads 360-1 and 360-2 are two versions of the company’s aluminum Mopar small-block heads. The 360-1 is the rectangular-port version and the 360-2 is the oval-port version (similar to the W2). The 360-1 has a 210-cc intake port, 2.100-inch intake and 1.65-inch exhaust valves, and a 63-cc heart-shape combustion chamber. It also uses .800-inch offset intake rockers.

Many options are offered, such as rocker shafts or Jesel rockers, 10-bolt or 18-bolt head bolt patterns, and several porting options. The stock intake port flows 280 cfm at .700 inch; bowl-port and intake match yields 290 cfm. Super-modified porting yields 309 cfm, and the full porting and polish yields 339 cfm, both at .700-inch lift.

The 360-2 oval-port Indy aluminum head uses a 180-cc intake port and flows 252 cfm at .700-inch lift. The chamber is 63 cc, the intake valve is 2.100 inches, and the exhaust valve is 1.65 inches. In its full CNC-ported configuration, the port size increases to 230 cc and the flow goes up to 322 cfm at .700-inch lift.

B1-BA Aluminum Heads

Koffel’s Place designs and Brodix casts the B1-BA Mopar small-block aluminum head. It features 18-degree valves with 2.08-inch intake and 1.60-inch exhaust valves. The exhaust pattern accepts standard headers. Production A-engine intake manifolds and stock, five-bolt valvecovers can both be used. The stock intake port is about 195 cc and the stock combustion chamber is 65 cc. The standard setup uses shaft-mounted rockers.

Many options are offered, including CNC-porting. Recent CNC-ported intake ports have flowed more than 370 cfm.

Cast-Iron Heads

All the cast-iron heads pretty much disappeared in the early 2000s. Cast iron is difficult to pour in limited quantities, and many cast iron foundries have gone out of business. So until about 2014, cast-iron heads were not easy to find. Indy Heads introduced a cast-iron version of its aluminum head and produced it in an A-engine version (with rocker shafts) and in a Magnum version (8 rocker pedestals). Both are machined from the same casting.

Cast-Iron Indy Heads

Indy Heads offers cast-iron 360 LA-X heads for the A-engine, which feature five valvecover bolts and the dual-exhaust bolt pattern. The cast-iron A-engine head has chamber volumes of 62 cc, intake port volume of 179 cc, and valve diameters of 1.92-inch intake and 1.625-inch exhaust (with 2.02- and 2.055-inch options).

The company also offers heads for use with .525-inch lift (hydraulic cams) and .600-inch lift (mechanical cams). The .525-lift version is for hydraulic cams but can be used with low-lift mechanical cams if desired; there just aren’t many mechanical cams that lift only .525 inch. The .600-inch-lift version, a mechanical cam, is most often used because very few hydraulic cams have lifts in the .525- to .600-inch range. The valvespring is the change and valve lift is the key. These heads also use 5/16-inch valvestem diameters and stainless valves.

Caution: These heads use five extra-long head bolts similar to the Magnum, plus they may not use standard 340/360 spark plugs. Indy Heads also makes a cast-iron head for Magnum engines called the 360 MA-X. Its specifications are similar to the above A-engine head with valve size and spring options. The Indy Heads cast-iron head is the best available today. Both A-engine and Magnum versions are available. Both of these iron heads feature a 62-cc chamber.

Bare Heads

Several aftermarket manufacturers offer bare (rough) heads. Chrysler referred to these as partially machined heads; Edelbrock called them raw or semi-finished. Essentially, the head has been machined with the exception of the valveseats, combustion chamber, and ports, which are as-cast. In most cases, the valveguide hole is machined, but guides may or may not be installed. These heads provide engine builders the latitude to machine the heads to specific requirements, and therefore can be CNC-ported. Most manufacturers offer this option, but only Edelbrock puts details in its catalog and on its website.

Cylinder Head Selection and Prep

When selecting the head for your build, focus on three features: material (cast iron or aluminum), valve size (intake and exhaust), and peak intake flow. Although there’s more to a cylinder head than these specifications, they are very important. With so many head models, designs, port sizes, and combustion chamber shapes available, you need to select the head for your build very carefully. There should be no reason to hunt through junkyards and hope you find the specific head for your performance use.

Several considerations must be addressed first, such as aluminum versus cast iron and repair versus new versus used. Cast-iron (Indy) and aluminum heads (Edelbrock, B1-BA, Indy) are available today that do a good job for the Mopar/Chrysler small-block. Originally, cast-iron heads were less expensive but today cost close to the same as aluminum heads. Aluminum heads offered more flow, but that may not be the case today, short of the W9 head and CNC-ported heads in general.

Overall, I do not recommend going the used route, but there are exceptions. So the choice comes down to buying new or doing repairs. The Indy Heads, Edelbrock, and B1-BA/Brodix are excellent choices for max-performance street use. The best small-block head is the W9, either as-cast or ported. Availability is the factor. The W8 head was a good head but is no longer available. To recommend it, the head must be cost-effective and readily available, so the Edelbrock aluminum head is my first choice.

Cost is the deciding factor between the Indy head and the B1-BA. Brodix provides more technical information on the B1-BA in its catalog and the company offers both the standard 18-degree valve angles and the 15-degree angle that were common in the W8 and W9 heads.

All three manufacturers offer CNC-ported versions and there seems to be more information on the Brodix and Indy Heads versions. Based on fl ow numbers, the CNC-ported Indy head makes 339 cfm with a 2.100-inch intake valve, and the CNC-ported Brodix B1-BA makes 347 cfm with a 2.14-inch intake valve. Brodix shows the stock or as-cast B1-BA fl owing 269 cfm, which is also very good. CNC-porting makes more horsepower but a full porting job is probably not needed for the street/ strip application.

Remember that other specifications must be kept in mind too. They include: compatibility, port volume, bolt patterns, and combustion chamber type.

Best Mopar Heads

Compatibility All parts of an engine must function as a complementary system. One cylinder head is not best for all applications. So you need to carefully select the proper specifications for your goals and build. The valves must work with the port, as finished, and the port-valve combination must work with the cam selected. You do not want to use a .700-inch lift port with a .500-inch lift cam, or a .500-inch lift port with a .700-inch lift cam, which are common pitfalls to avoid.

However, the exhaust and intake manifolds, throttle body/carburetor, and cubic inches all play into the same equation. For example, in NHRA Stock and Super Stock classes, which allow only limited modifications, the 340 and 360 engines (using the same head and induction system) do not work well with the same cam, converter, gear, etc. Simply put, the 340 sets up like a short-stroke engine and the 360 sets up like a long-stroke engine.

For an interesting comparison of how heads and cams, valve lift, and compression ratio work together to change the engine’s operating band (engine RPM), torque, and horsepower outputs based on horsepower per cubic inch, you can review Edelbrock’s five basic packages. They include upgrades from 250 to 325, to 400, to 470, to 610, and to 720 hp based on Edelbrock heads and hardware. Information is available on the company’s website under “Power Packages.”

Port Volume

Many aspects of a cylinder head affect actual port volume. Although valve size stays the same, a slight tweak (grind) on the valveseat sinks the valve slightly and changes the port volume. Changing the valve from a tulip valve to a nailhead valve changes the port volume.

Milling the intake manifold face to make the intake manifold fit after milling the deck surface changes the port volume as well. Any porting that is performed also changes the port volume. That is why port volume is not used as a control specification but as a general guideline.

Intake and Exhaust Bolt Patterns

The Mopar A-engine intake bolt pattern is perpendicular to the manifold face; the Magnum pattern of the attaching bolts is vertical. The 1964–1965 273 heads also used vertical intake attaching screws. Also, the W-series heads, such as the W2, used a wider-spaced attaching bolt pattern for the bolts on either side of the actual intake ports.

The end bolts stay in the same location because the bigger intake ports are best for the higher-flowing ports in performance applications. End bolts stay in the same location (only the ones next to the ports move away from the ports) to gain wrench clearance for the ones on the inside of the turn. The intake manifold must match the cylinder head ports, so the larger runners crowd the inside-turn manifold bolts (the two closest to the center of the engine) to the extent that you cannot put a wrench on the bolt head. Widening the spacing solves this problem very easily.

The A-engine and the Magnum use the same exhaust bolt pattern. The original W2 cast-iron head spreads the exhaust bolt attaching pattern away from the ports. In the second generation of W2 heads, either the standard pattern or the wider W2 pattern was machined into the head. You should plug the holes in the dual-exhaust pattern that are not used to attach the exhaust manifold/header; use small Allen screws and seal the threads. Indy uses this dual-pattern approach. The the Magnum exhaust side uses spark plug shields inserted into the head.

Combustion Chamber Type

Many aftermarket performance heads use a machined chamber, so it is easy to revise. The typical A-engine head uses an open chamber; the Magnum engine uses a closed (bathub) chamber.

The third-generation W2 offered a closed-chamber head as an option with volumes in the 47- to 55-cc range (standard open-chamber volume was 70 cc).

Many aftermarket heads use a heart-shaped chamber. Most chambers are really a modified heart shape, which is pretty close to the bathtub shape. Relieving the chamber around the valves for increasing the port’s airflow enlarges the chamber slightly and tends to make the heart into more of a bathtub shape.

High-Performance Valve Job

The two parts of a valve job are half to the valve and half to the cylinder head. Aluminum heads use a valveseat insert into the head; cast-iron heads typically grind the valveseat directly into the casting, but seat inserts can be used for repair purposes. One of the secrets to a valve job with any valve insert is to create a smooth transition from the port to the valve job and into the chamber. This is one of the advantages of CNC-porting, if the CNC machine does the port and the valveseat.

Valve Centers

Almost all A-engine and Magnum heads use the same 1.87-inch size for valve centers. The W9 uses 1.936-inch valve centers for large valves. Aftermarket heads can be modified to add a 1.936-inch valve, but most are built with a 1.87-inch valve.

Air Pump Holes

Most newer A-engine production heads have emission air pump holes in the exhaust flange just below the exhaust port on each cylinder. If the heads are going to be used for racing or other performance purposes, plug the threaded hole with an Allen screw. If the air pump holes are left open, they leak exhaust gas when headers are installed.

These holes are not machined on the 360 high-performance (E58 option) or the 340 cast-iron heads.

Rocker Stands

Rocker stands fit between the rocker shaft and the cylinder head; basically, they replace the cast-iron rocker pedestal. To use rocker stands the machine shop machines off the pedestals. The most common use of rocker stands was for race W2 heads. The rocker stands allowed the rocker shaft to be raised, which allowed a longer valve and taller valvesprings, and offset away from the valves, which allowed the rocker arms to be stronger (no increased relief on the underside). The econo-W2 head used as-cast pedestals.

Special Head Considerations

Many cylinder head and overlap features are important to the engine’s operation and performance. Compression ratio and airflow are key players in the performance equation and are affected by the cylinder head.

Compression Ratio Measurement

The first step in measuring your engine’s compression ratio is to cc the combustion chamber in the cylinder head. Initially, you only need to measure one chamber. I recommend one of the two center chambers. To cc the combustion chamber in the head, you need the following: a 100-cc burette; a flat, clear, 1/4-inch thick Plexiglas plate; a cc-ing fluid, such as parts cleaning solvent or rubbing alcohol with food coloring added; and a light grease such as petroleum jelly.

Compression Ratio Calculation

The formula for calculating the engine’s compression ratio is detailed in Chapter 3. Basically, it is the VBDC divided by the VTDC. The biggest part of the VTDC is the chamber volume, which must be cc’d. You want to know your basic compression ratio as soon as possible so you can order pistons, mill decks, mill piston tops or to have the compression ratio where you want it for your application and fuel use. If you are shooting for a compression of 9:1 and you find that it is 10:1, you must lower the ratio by one point. If you are building the engine, a new set of pistons is the best solution. If it is already built, try a thick-head gasket or shim. If the ratio is 8.5:1, you could probably mill the block and heads to gain the 1/2-point of ratio. However, if it is 8:1, new pistons are best because it would require too much milling, which causes other problems.

Displacement Calculation The first part of the compression ratio equation, or VBDC, is basically the displacement of one cylinder plus the VTDC. This makes it important to calculate your exact cylinder displacement. For example, if your engine has a 3.94-inch bore and a 4.00-inch stroke, the displacement is 390.15 ci (8 x .7854 x 3.94 x 3.94 x 4.00).

For use in your compression ratio calculation, you only want one cylinder’s displacement (sometimes called swept volume), so you divide the displacement by the number of cylinders. In this case, it’s 48.77 ci (390.15 ÷ 8).

To use the number in the compression ratio formula, you need to convert this volume to cubic centimeters, which is 799.17 (48.77 x 16.387).

Shrouding The combustion chamber allows the valves to open into an area on one side, next to a valve. For about 90 degrees, where the valve is next to the chamber wall, the valve is shrouded as it lifts off the valveseat. On production cast-iron heads, a valveseat cutter generally relieves this area for each valve. Enlarging this basic relief helps airflow. How

ever, you must not get carried away because the seal ring on the head gasket must seal to the head surface in this area so any increased relief must stay inside of the gasket’s seal ring. This is commonly performed on aluminum heads, especially the ones that are CNC’d.

Valves

A-engine and Magnum engine valves open on-center. Simply put, this orientation means that the head diameter runs across the widest part of the bore. As a result, big-valve 340 heads can be used on small-bore 318 blocks. It also means that if the valves are the same size, such as 2.02 or 1.60 inches, the valves are less shrouded as they approach max lift.

Magnum engines and A-engines do not use the same valves. Because the diameters are slightly different, the Magnum uses a slightly shorter valve by about .060 inch. It also uses a thinner valvestem. They are not interchangeable.

Length

The Magnum intake valve has a length of 4.91 inches and the exhaust length is 4.92 inches. A-engine intake valves are 4.98 inches long and the exhaust valve lengths are 4.97 inches.

Race versions of the W2 and W5 A-engine heads use .300-inch-longer valves, 5.28-inch intake and 5.29-inch exhaust. This increases the valvespring installed height from 1.70 to 2.00 inches. More installed height allows the use of bigger springs, which allows more valve lift, which works with the big ports that flow more air at high lifts. Some aftermarket heads use longer valves with the increased installed height/max valve lift.

Stem Diameter

A-engines, both the 273/318 group and the 340/360 group, use 3/8-inch valvestems. All Magnums use 8-mm valvestems, which is very close to 5/16 inch. In the aftermarket, 11/32-inch valvestems are popular. Some aftermarket heads use 11/32 x 5/16 stems.

Head Diameter

The 340 valves’ head diameters are the most popular at 2.02 and 1.60 inches for the A-engine. The 1.88-inch intake (360) is also popular. Oversize valves, such as 1.65-inch exhaust and 2.08-inch intake, are also common. If a 2.15-inch intake valve is to be used, wide valve centers must be used. The Magnum uses a 1.92-inch intake valve and a 1.625-inch exhaust valve, with oversize intakes of 1.97 and 2.02 inches also available.

Material

Both intake and exhaust valves are made from steel. In general, the intake and exhaust are not made from the same steel alloy. The exhaust valve sees more heat so it uses a special alloy. Most aftermarket performance valves are made of stainless steel. Stainless steel is also harder and stronger than standard valve material and this hardness helps the engine if unleaded gas is used. Stainless offers an option to hardened valveseats.

For max-performance applications, the aftermarket offers titanium valves, which are considered race-only parts. They are lighter than stainless valves and are also strong, but they are quite expensive. As valve heads become larger and valves become longer, they are heavier. Titanium is one way of making the valve lighter without giving up diameter or length.

Valve Seals High-performance valve seals are made of high-temperature Viton. The standard A-engine valve seal has an umbrella seal that slips over the valvestem; the Magnum valve has cup-style seals that fit over the valveguide and must have the guide sized to accept it. Seals must be inserted inside the valvespring. The umbrella seals fit inside of the single spring; the dual spring does not. High-lift cams use dual springs.

One option is to use a PC seal in place of the umbrella seal. The PC seal fits over the guide and requires the top of the guide to be machined to accept it. Also, this seal requires .100-inch clearance, so you lose the thickness of the seal off the valve lift. If you plan on running on the street, you want to use a production seal (umbrella or Magnum-style), which means using a single spring with dampener (optional). There are good single springs that allow .500-inch valve lift, up to .535-inch valve lift.

Head Gaskets

Today most of A-engine and Magnum head gaskets are about .040-inch thick. Most use MLS construction.

Four- and Six-Bolts

The production small-block gasket uses four bolts around each chamber (10 bolts per head). For very high compression ratios and racing applications, Mopar/Chrysler introduced blocks and heads that featured six bolts around each chamber (18 bolts per head). Cometic, Fel-Pro, and others offer special six-bolt head gaskets for this application. The W8 and W9 heads were designed for the six-bolt pattern.

The six-bolt pattern is designed so that if you have a six-bolt head or block but do not want to use this feature, you can use a standard four-bolt gasket. For example, if you have an R3 bolt with the six bolts machined, but you have an Indy four-bolt head, you can use the four-bolt gasket and leave the extra bolt holes empty.

Street Supercharger

Several aftermarket companies offer street supercharger kits for Magnum engines, and most kits are set up for the Dakota, Ram trucks, or Jeeps because the engine compartments are large. Magnum engines in these vehicles were built with a compression ratio over 9:1, but a supercharged engine on pump gas (92 octane) should have an 8:1 compression ratio. If the ratio isn’t changed, the engine detonates and breaks parts, blows head gaskets, scuffs pistons, etc.

Changing the pistons to reduce the ratio one full point is expensive and time-consuming. The bible fraud pdf. Cometic offers an MLS gasket that is .120-inch thick, which drops the engine’s compression ratio about one full point and solves the problem.

Copper Head Gasket

Copper head gaskets are suitable for supercharged race engines because they support high compression. Typically they are used with O-rings. They come in thicknesses of .042, .051, .062, and .081 inch. Manufacturers also offer special bore sizes. If the copper gasket is not damaged, it can be re-used.

Written by Larry Shepard and Posted with Permission of CarTechBooks

GET A DEAL ON THIS BOOK!

If you liked this article you will LOVE the full book. Click the button below and we will send you an exclusive deal on this book.

http://www.moparchat.com

http://www.moparchat.com

http://www.moparchat.com

http://www.moparchat.com

http://www.moparchat.com

******************

TOPIC: 383-Magnum BuildUp

by 70Chall383 on 01-29-2000 08:36 PM

I want to build a 383-magnum that is a step above stock but still have a high school kid be able to pay for gas =) and suggestions? Also this may be kind of a stupid question but what do you think would win in a drag, a 1970 Challenger 383-magnum or a 1970 Chevelle SS 396?

Mike

------------

REPLY by Christopher on 01-29-2000 11:22 PM:

It really all depends on how much money you want to spend!! I'd use a Edelbrock/Carter/Holley 750cfm carb,Edelbrock Performer intake or the factory 383 deal,shoot for 9.5:1 compression ratio,mill the heads to get at 80cc's(probably about .040)use the 272/455 Mopar cam,or if you want a bit more use the 280/480 Mopar cam.Do a nice valve job,and use the Mopar porting templates,Mopar electronic ign setup.I'm guessing you have a automatic trans.If so, I'd use a converter around 2000 stall.Use a 3.55 gear.Exhaust can be factory manifolds,use 2.5' pipe and a good set of mufflers.As for your question about which engine would win,I'd lean toward the 383 anyday!!

------------

REPLY by sublime70 on 01-30-2000 12:33 AM:

I'd say Chris is on the money. 10 years ago I had the experience of riding along in a friend's '73 Rallye Challenger (auto/3.91 gears) when it walked off and left a fairly hot '70 396 4 speed Chevelle. The 340 was more or less stock, but with a typical rebuild (little more compression) and some type of mild smooth-idle cam. That experience turned me on to Mopars. The Chevy kid almost cried, and sold it to buy a GTO. Some improvement. Don't let the Chevelle guy give you any crap. Your car is ten times more rare and that 383 will outlast that 396 boat anchor by many years.

------------

REPLY by 383boy on 01-31-2000 10:13 PM:

Since the horsepower is close to eachother and a challenger is lighter than the chevelle, you have a good chance at tie but giving that the horsepower of the chevelle is more, I feel that the chevelle will win.

383boy

------------

REPLY by 360duster on 01-31-2000 11:02 PM:

You had better take a closer look,it might be a 454 since 396`s don`t usually live to be 30 years old.I raced a 66 ss396 once that turned out to be a 454.It didn`t mater though i still beat him with my 360 Duster.He couldn`t get all that power to the pavement.

------------

REPLY by sublime70 on 01-31-2000 11:09 PM:

If you really want to toast those Chevy's here's what you do, kid. Save your money, dig ditches, steal from old ladies on the sidewalk, whatever you have to do, get yourself about $400 bucks and order a plain-jane, bare-bones plate nitrous kit from Summit or Jegs. Make sure you have a good fuel pump, like 7 psi at at least 100 or so gallons per hour. Put that 383 back together with a mild cam, decent headers, and good ignition. Install that plate on the intake and paint it to match, epoxy it and sand it down smooth if you have to. Get some various and crusty old mopar engine stickers and put them on the solenoids (after they are painted black, or other discreet color). Believe it or not, most Chevy gearheads will either not notice it or will believe it really is emissions equipment if you BS him a little. Tell him it's EGR or part of the PCV system. This goofy low-buck cheating strategy worked for me all through high school. Even though my '84 Stang wouldn't fall out of a tree when off the bottle (14.10's), i------------

REPLY by hemi-1 on 02-01-2000 08:54 AM:

Just because the SS396 was rated at 350 horsepower vs. the 383's 335 doesn't mean that it really made more horsepower. Horsepower ratings in the 50's and 60's are notoriously inaccurate. I'd pick the 383.

396/375's (not available in 1970 I don't think) were pretty quick, but not the 350 horse versions. Lot more than 25 horsepower difference between the two motors. In 72 or 73 my Dad raced a 70 SS396 with his stock 71 Duster 340 with three-speed stick and outran it three times out of three. The SS 396 had headers too.

As for the 454's, a very few of them in 1970 were the 450 horse versions and were pretty stout, but most were the small port 360 horse versions that were only a little quicker than the 396's.

In the early 70's my daily driver was a 65 Barracuda with a low compression 340 that was stock except for heads milled .030, aluminum intake and 780 Holley, with a 4-speed and 3.23 gears. Just cruising around on the streets, I never came across an SS396 that would outrun it; only encountered two that could stay with me, most couldn't come close.

There's always some that are faster, of course, but a typical stock 350 horse SS396 was just a low 15 second car. No big deal.

------------

REPLY by 70Chall383 on 02-05-2000 01:23 AM:

How does the 383 handle nitrous as far as wear and tear? There is a '69 firebird formula 400 at school that i would like to give a good run =)

Thanks for all the responses

-Mike

------------

REPLY by Christopher on 02-05-2000 07:48 AM:

You shouldn't need nitrous to kill that tin indian.But if you must,do what sublime 70 has said,and go easy on the timing,you'll probably have to retard it some.The 383 can handle the 'gas,just be sensible about it.And as a side note,try to keep your racing on a track,and make sure you have a seatbelt on.

------------

******************

TOPIC: w2 heads on 360.?????????

by ROWDY on 02-05-2000 02:38 AM

I've put the 588b1 on hold for some street fun.I'm looking at building a 360 with aluminium w-2's.The plan was w5's but i was told the oil galleries were'nt matching with the block(destroying valve gear)and mopar didn't want to know about the problem.

So i'm looking into w2's but nobody here has ever used them,so i'm looking for some experiences with performance of the head.The combination as such is still undecided but will be running n02 for that extra fun.

Any suggestions will be much appreciated!!!

------------

REPLY by Christopher on 02-05-2000 07:41 AM:

I haven't seen any aluminum W-2's from Mopar,just the ones C.J.Batten made years ago.But I 'd use a set of W-2's in a heartbeat,whether they be iron or aluminum.These are very good cylinder heads in my opinion,and I'm kind of surprised that more people don't use them.They are plentiful on the used market as well since Mopar started making them in 1976.

------------

******************

TOPIC: new 360 stroker crank

by 360duster on 02-04-2000 10:35 PM

I saw somewhere that MP was producing a 4.0 stroke cast crank for the 360 that is resonably priced.Does anyone have info on this?If so do they have pistons too?

------------

REPLY by 440Ramcharger on 02-05-2000 07:36 AM:

As far as the 1999 MP catalog goes, there is a 3.79 stroke. Part # P4452979. These are 4350 steel billets.

Z

------------

******************

TOPIC: Big valves or not

by Glen440 on 01-31-2000 11:45 PM

I have a Volare Roadrunner with a 440.

The motor is .030 over with 10.5 Trw slugs, stock crank and rods with Arp bolts.Right now it has the .528 Purple shaft cam in it. ported 452 heads with stock valves,torker intake, 750 holley, 1'7/8 hooker hedders, 727 with factory high stall and 4.30 gears. I am wondering if putting a set of 906's with 2.14, 1.81 valves on it will make a big improvement.I have a set of professionally ported 906's that the valves are sunk. The car has not been to the track since I replaced the 400 with the 440.So I have no baseline, but the motor is coming out soon so this is the time to do it.

The 8-1 compression 400 ran 13.15's all day long with the top end from the 440 and 3.91 gears. I am thinking that the 440 should be good for high 11's. The car weighed 3750 with out driver. Peoples advice is appreciated.

------------

REPLY by Chris A on 02-01-2000 12:30 AM:

You have a decent combo and should definantly be running the bigger valves. I would just get the 452's pro ported and put the valves in them if the 906's are sunk. They have the same basic port configurtion except for one or two spots. Check out the other topics on 452's VS 906's. Good luck.

------------

REPLY by DartGT66 on 02-01-2000 02:37 AM:

The bigger valves and bowl porting is definitely a good help in a big block. Do the 906's have stock size valves that are sunken, and you could bring them back to surface with the bigger valves? If that's not the case, don't bother, valves that are sunk are not a good thing for performance. Instead, put the big valves to your 452 heads.

------------

REPLY by MopART on 02-01-2000 10:39 AM:

Ditto... I can affirm what has already been said. LET THAT MONSTER BREATHE.

------------

REPLY by Krep on 02-01-2000 12:19 PM:

I agree with the others, bigger valves make the 906 and the 452 come alive (with proper porting). Also when the valves are sunk there is a loss in performance. Keep the valve up as fare as possible. If you are on a buget, increasing the exhaust valve size has greater benifits than the intake. So if you have to choose..

------------

REPLY by Glen440 on 02-01-2000 11:01 PM:

The 906's have stock valves still so going to the bigger valves should fix them. Should I get hardened exhaust seats? The car will be driven daily as long as It doesn't cost too much to drive it. I've priced head work

and looks like for machining, guides, and stainless valves around $800cnd.

------------

REPLY by 340king on 02-01-2000 11:50 PM:

I have to disagree about the need for bigger valves. My engine builder has ported many a RB head. They have optimized the port for the stock valves. Then tried another port optimized for the bigger valves. Both ports flowed the same. Now, I have posted this info before and was basically called a liar. It is the truth as I see it and have a lot of faith, nearly $13,000.00 worth, in my engine builder.

I did post way back the flow numbers they were getting from the stock valves and that was the source of the disbelief. Since you already have the bigger valves, you are not out anything to go there. Just remember they in themselves are not a magic bullet.

------------

REPLY by DartGT66 on 02-02-2000 01:09 AM:

Well, you can't optimise a head with sunken valves, can you? But you can fix them with bigger valves. I odn't call you a liar, maybe your machine shop just knows something that all others do not. However, I have homeported several sets of BB heads. I do not have a flow bench, so the only way to verify how the heads work is to drive them at the track and verify the performance. And according to my experience and with my skills, porting the heads with stock valve size leads to a performance gain, and installing bigger valves and porting the heads makes the cars run even better. And in the case of BB even with pretty small cams. But ofd course it costs some too. I can't take the same performance out of a 2.08/1.74 head that I can from 2.14/1.81 head.

------------

REPLY by Speedy#1 on 02-02-2000 03:19 AM:

I'd have to agree with 340king i would say larger port's and good modern valve desighn would give you more bottom and high range .

------------

REPLY by Tim_K on 02-02-2000 12:28 PM:

Everyone says sunken valves cost power, so it must be true, but I've never heard a good explanation of WHY this is. Extra cc's in the chamber, reducing compression? The valves are now blocking part of the port? Something else? What?

------------

REPLY by ChristianCuda on 02-02-2000 12:50 PM:

Since everybody elses 2 cents are here I might as well cloud the masses with my added 2 cents.

On big blocks all heads will warm up to template porting. But the bigger valves will depend on each application and also the 452 will perform better to porting that the 906 due to a constriction on the 906 casting that is not on the 452 or 346 castings. I have stated all this in other posts. The bigger valves are not always needed but one thing that is shown is that the 1.74 valve is way to small for a big block to breath. Imagine if you could open you mouth wide for intaking air and then had to exhale only through your nose. It takes longer to get all that air out well same goes for the heads. I always increase to 1.81 exhaust valve but keep the 2.08 intake. going any larger then needs more deshrouding on the head and cylinder to make any better power. And with a properly ported intake port the 2.08 flows very good for a motor under 600 horses which is most of our motors. Especially a street motor that is naturally aspirated. Now if you have a blower or turbo than you would benifit more with a larg

Anyway I thinks thats more than 2 cents worth.

Christian

------------------

68 'Cuda 383

Working on adding EFI

------------

REPLY by 340king on 02-02-2000 11:08 PM:

Tim the reason for the drop in performance with sunken valves is the shrouding that takes place at low lifts. Valves are opened quite slowly on the bottom of the lift and spend quite a few degrees just getting to .050' lift. Imagine shrouding the valve for even .010'. This would effectively decrease the duration of the cam quite significantly, as flow would not start until the effects of the shrouding are overcome.

You bring up a good point Christian. Why put larger intake valves in a head design that flows so poorly on the exhaust. The flow balance on the cast factory heads is well below the 75% range. The exhausts need more work to get to optimum performance without increasing the intake flow. I just don't like seeing a guy spend money on bigger valves that could better spent elsewhere thats all.

------------

REPLY by DartGT66 on 02-03-2000 02:53 AM:

The low lift thing is only one point; it can be cured by reworking the chamber and that's what I always do in the heads I work with. Another thing that the short turn in both the intake and exhaust is too low in both intake and exhaust ports in mopar heads. When the valves are sunk, the port floor comes even lower, not a good thing. With bigger valves you gain more height in both intake and exhaust and can make a better working radius there.

------------

REPLY by Speedy#1 on 02-03-2000 12:21 PM:

iS that the only way you can raise the valve hieght is buy using larger valves?I can understand larger valves on the exh but why spend the extra cash on the intake?I was wondering because i may bee doing this myself in the year or so.

------------

REPLY by chrisfly on 02-03-2000 06:39 PM:

I have to agree with the majority here. You are running a pretty good cam and porting the heads with bigger intake and exhaust valves will wake this machine up. Just be careful when porting, bigger isn't always better. If this is a dual purpose machine, I would do a mild to medium port job to keep the velicity of the mixture up. You ideally want 350 400 cfm for optimum power. If you port too big, you will lose your velocity and the thing will be a dog on the street. A good website to take a look at is www.hughesengines.com. They have complete stage1,2,3 heads with big valves at a reasonable price. I bought their stage 1 heads and am running a 540/550 lift camshaft. Hope this helps

------------

REPLY by Glen440 on 02-03-2000 09:10 PM:

Thanks Guys!

I'm going to go with 340King and just port the 452's and keep the stock valves. I ported them a couple years ago as close to the mopar templates as posible. I'm going to clean them up and use them another season.

I'll get the 906's done in the summer and I'll get to see the performance gain! I'm sending the short block out instead. Its time for rings and bearings. I bought it off a guy who had it built 16 years ago. It was driven hard enough to break hemi springs!

Thanks for advice

Glen440 ~Mopar forever~

------------

REPLY by ChristianCuda on 02-04-2000 02:56 PM:

Glenn Since you mentioned springs i remembered. Make sure you put New or Known Good Valve springs on that 452 head cause without it all the work is for naught.

Christian

------------------

68 'Cuda 383

Working on adding EFI

------------

REPLY by Christopher on 02-04-2000 06:47 PM:

I'll throw my 2 cents worth on this,and I'm agreeing with what most of you guys have said.On my 440, I have 452's with the big valves and no porting or bowl blending,they are as factory produced except the chamber cc's are at 80.I also have a set of 906's that have the stock valve size in them and they too are at 80cc's.I wanted to see if the bigger valves really were worth the extra money as I have several sets of NOS small Mopar valves on the shelf.I swapped the 452's for the 906's and the car slowed down 3 tenths in the 1/4 mile.I swapped the 452's back on and the following weekend,the car went back to running 11.30's.

------------

REPLY by ROADRUNNR on 02-04-2000 09:32 PM:

has anybody read mopar muscle jan,feb &mar 99 issues about bb heads? they claim bigger valves in 346&452 castings with minimal porting is the way to go. they claim what really makes these heads breath is a 30 degree seat.

------------

REPLY by ehostler on 02-05-2000 06:47 AM:

What is the minimum over-bore to get the 2.14/1.81 valves to work in a 383, without interfacing the cylinder wall?

------------------

'96 Dodge Ram 1500 SLT CC 360 4X4

'68 Charger 383-4

------------

******************

TOPIC: MOPARS STAGE VI HEADS

by carbkid on 07-23-1999 12:21 AM

JUST PURCHASED SET OF ALUMINUM STAGE VI HEADS ANYONE HAVE ANY EXPERIENCE WITH THESE CARBKID

------------

REPLY by Cudaloco on 07-23-1999 06:39 PM:

I've been wanting a set, but I figured if I go with a new set of heads (I've got 908's now)I wanted something with an angled plug to bring it in the bore centerline..like the new Max Wedge StageVI. Did you get the standard or the new MW? Keep the rest of us informed on how they do, no matter which set you went with!

------------

REPLY by Christopher on 07-23-1999 10:57 PM:

My understanding is that these heads are no better flow wise than a stock set of 906's.I also understand that they need to be ported and the bowl area blended then they really come alive.They are a good set of heads.I also like the fact that they don't need alot of expensive parts that the Indy's do.

------------

REPLY by carbkid on 07-24-1999 03:05 AM:

CUDALOCO, I got the standard straight did not know about MW's till Mopar Nats but I did get them bran-new inthe box with valves for under 1400 off the internet mopar alley classifieds. Serno heads will bowl port them to flow close to stock B-1's. Need to find out cc,s to work with my 13;1 forged pop up's. I read you can mill them to at least 76cc's straight plugs will work well with my pistons w/plug notch in dome. I want to take advantage of high compressions awesome power burst.

------------

REPLY by sanborn on 07-26-1999 09:54 AM:

We worked a set of these several years ago with good success. Our application was oval track, yours is probably different. The location of the spark plug dictates a different approach. Use .000' deck height (with billet steel rods). Mill .100' to get the CC to about 75-76. Just clean up the combustion chamber (equalize CC), Use a dome height of .100' and closely match the dome to the combustion chamber. Use minimum valve reliefs, .040' intake and .100' exhaust clearance. This will get you in the 13.5-14 to 1 area. In the exhaust port, raise the roof .200' and form into a 'D' shape. Do not touch the floor other than clean up. The port width should be 1.800'. Very carefully raise the port roof in the guide area, remove as much of the guide as possible without removing strength. Use a 1.800' valve. Flow will be in the 240-250 CFM area @ 20 dominator. We ran 32-34 degrees advance. We also modified the water flow to help cool the exhaust valves and seats. Drill a 5/8' hole between the center exhaust valves in both block and heads, restrict the flow at the back of the block with a freeze plug with a 1/2' hole drilled in it. The ports do not stall so you should be able to use .750' or more lift. Because ours was an oval track application, we used only a .680' lift for better valve spring life. These heads love RPM, plan to turn your engine 7800-7900 RPM with good power. Use either aluminum main caps or 4 bolt caps. Our engine with the heads modified as described produced 745 HP.

------------

REPLY by Rue on 01-04-2000 01:03 AM:

Hi dude's talkin about MP Stage VI Heads, I have a pair to put on my 440. The heads I have are P4876311. I understand that these can be bolted on to an RB without the spacer package. (at least that's what the guy said) The ones I purchased were still in the box and I had the keepers and retainers upgraded to 10 Deg types and springs upgraded for use with the P4120663 camshaft.

I have ordered P5249506 Stage VI porting template kit. In the MP Performance Catalog it states that these particular heads are 'Street Stage VI' .. what does this mean? Is there differences between the Stage VI's ie. apart from the Max Wedge types etc.

I havn't a clue as to what this things goin to go like .. its goin into a backhalve 68' Dart with 5.14 gears, 4 Link and 16x33 Slicks. It's got H-Beam 4340 Rods, top and bottom Stud Kit, Holley HP950DP, M1 and MSD7AL2 etc. It should tip the scales around 3200lbs when completed. I would love to hear from others who have similar combo's. I live in New Zealand and MoPars are kinda thin on the ground here. But what one's there are here - are 'KickButt' Chryslers - no worries. Thankyou.

------------

REPLY by DartGT66 on 01-04-2000 03:37 AM:

I have had the Stage VI's for many years. The chambers were 84-86 cc out of the box. The bowls actually have a lot of material, and it's no wonder that in stock form they do not flow more than the stock iron heads. At the time I got my heads there were no porting templates available, so I ported them without the templates. Later I bought the templates, and they matched the bowls almost perfectly. These heads were first on a mild 440, and were a big power boost over the iron heads. Some other small mods were done at the time, so I can't honestly compare them to the template ported iron heads, anyway the mph went from 109 to 116.5 mph. I think these heads are best oriented for street; there are better racing heads available that need less work to perform. I even think that in a wilder street engine the B1/BS or Indy SR heads are a better choice. Currently the Stage VI's are on a '451' short block; the spacers are history. I just didn't like the idea of spacers in the first place, the intake face angle is only 7------------

REPLY by Belvedere65 on 01-04-2000 09:04 AM:

Went from ported 906s, .590 cam, TRW

12.5 pistons to StageVIs,bowls cleaned

up, gasket matched, Ultradyne .640

cam, Ross 12.5 pistons,deck height

010. Car ran 10.90s @ 121 MPH with old combo & 850 carb. Runs 10.40s @126 MPH now, just shaking it out. Had to add Dominator to wake it up! Harland Sharp rockers hit valve covers on push rod side, changed to Cranes. Intake pushrod holes need clearancing to align with rocker.With more porting ETC. I am sure there is more there.

------------------

BFRACN

------------

REPLY by Christopher on 01-04-2000 05:59 PM:

Glad all of this info is here.I have been debating on a aluminum head setup,and you guys gave me all the answers I needed.

------------

REPLY by PRO on 01-04-2000 10:22 PM:

The Stage VI(6) head is 78cc's(all are closed chamber).Has 210cc intake runners and are of the raised design,the exhaust port is also raised.You can mill them quite a bit as they have a .450 deck.In aluminum you save 40lbs. and gain 40hp over stock 906/452s.Stock valves sizes are 2.14/1.81. P4876311 needs no int adapter to use stock intakes.Dont confuse this with the 'older Stage V(5) head,as it was a stock repacement head w/stock flow.Stage 6 definitely has a flow advantage over stock heads and if you buy P4876186 you gain 12% int and 20% exh flow.If you buy the P5249523 you get 2.18/1.81 valves and gain 20% int and exh flow.Remember the aluminum dissapates heat much better than cast iron so you can gain 1 full point of compression w/o detonation. 10.5-11.0 works well on 92 octane w/these heads.One note though if you have a short duration cam dont exceed 10.5.Go Fast..PRO..

------------

REPLY by DartGT66 on 01-05-2000 03:10 AM:

Pro, have you measured nay Stage VI's? Mine were 84-86cc out of the box, and I have heard about even bigger chambers. The exhaust ports have been raised more than what the advertisment tells, I once measured the bolt hole distance from the deck but don't remember it. They were raised way more than the 1/8' that the factory tells. I assume you base your 40 hp power advantage to the wedge crate engines? Whenever you read the 'articles' (=advertisments) in the mopar muscle where mr Shepard tells you how good the MP parts are, he always reminds the fact that the Stage VI's have a lot smaller ports than for example the Indy SR heads, 210 vs 260 cc, and therefore a better velocity. I think he doesn't remember to tell the fact that the Indy heads have longer valves, bigger short side radius and overall wider head, and therefore much longer ports. The Indys have raised ports too, but you don't have to use any intake spacers with them. So to compare the velocity thing you should add the spacer to the intake port displ------------

REPLY by PRO on 01-08-2000 01:17 PM:

Dartgt66,I'm just quoting MP on their spec,s,inaccurracies in cc measurement though is a given in my book,all burrettes are not made with the same precision as are not all chamber plates,to read 84-86cc when MP says 78 might on paper seem like a big difference but 6-8ccs is in reality about 4 drops of water,the most accurate burrete I've found has the smallest diameter of 1' and has the graduations molded in the glass.When I compare it to one that is 2 1/2' dia. and has painted graduations ,theres a 5cc difference at 100cc's.MP states 40hp gain and 2 fellow racers gained more than that when changing from stock 452s to stage VIs,both did slightly clean up the bowls as recommended by MP,1 car took .4 off his et and one .6(he also went to 2' headers vs 1 3/4')so I believe 40hp is actual.The exhaust port is substanstially raised as you said,MP claims a 70% flow increase!!! The P4876311 does not require an intake spacer when used on a RB,all other Stage VI heads do(there are 8 different Stage VI heads),I'm sure th

[This message has been edited by PRO (edited January 08, 2000).]

------------

REPLY by DartGT66 on 01-10-2000 04:13 AM:

I'm not using a burette when measuring the combustion chambers, I'm using an other medical instrument, I think more accurate thing, but I don't know what it is in English. I also doeble check the result using a weight scale accurate to 0.5 gram; I use water with a drop of soap to remove the tension, and since the water weighs 1 gram / cc I can weigh how much water I have put to the chamber, both systems give the same results so I think it's pretty accurate. I have not dealt with the end spacers, in my 440 stage VI I used self made spacers and a modified bath tube gasket to seal the lifter galley. I think that RTV seals almost anything and I use it enough. I can't straight compare the results with the Stage VI's since there were some other changes too. With the pocket ported iron heads the cam was a MP 280 hydraulic, with the Stage VI's a custom mechanical with 262 advertised degrees, but more lift than the 280 cam had. There was also more CR because I milled the block, about 9:1 with the iron heads and little amount of milling! My part supplier didn't have the 260/268 cam in stock that I would have liked to use, so I took the one step bigger 268/272 cam and installed it 4 degrees advanced to 104 degrees. I first thought about shimming the rocker shafts for pre load, but since the valve stem heights varied a little, I shortened the stock pushrods in a lathe. Those things are pretty hard stuff. Although I intended to use the 1.5$ quadrajet with the engine, the plan may change. I just got a Holley 6210-3 spread bore free, and will propably use that istead. No idea where has it come from, but it seems to be a replacement carb and even the choke systems etc. seems like a bolt on. But we'll see, more on that later..

------------

REPLY by Rue on 02-05-2000 04:21 AM:

Advice please .. I have a pair of Stage VI Heads (P4876311). I ordered a set of Stage VI Porting Templates (P5249506) from out of the MoPar Performance Catalog. I have recieved the templates and upon reading the Instruction Sheet it states that 'These templates can only be used on Stage VI aluminum heads, P4529335; they will not work on any other cylinder head, cast iron or aluminum'

What?!!

I surmise that because the Stage VI P4876311 is one of MP's latest offerings, and that the template kit P5249506 was offered before the advent of these particular heads that .. they will be Ok for using on my heads.

Comments?

------------

******************

TOPIC: hooker a body headers

by larry phillips on 02-03-2000 01:09 PM

ive got a nice set of used supercomp 2' fenderwell headers and was wondering if anyone had templates to cut out the fenderwells with it would be a great help to a guy new to mopars that is on a limited budget

thanks bigl

------------

REPLY by Dart on 02-03-2000 03:54 PM:

Have you run those headers before? I think they stink.

Here is why:

1)limited tire size on front of car

2)Heat in the engine compartment/floorboards

3)Butcher your inner fenderwells

4)2' tube is way too big unless you have over a huge cam and 440.

5)Exhaust set up is a pane (have to cut more out of the car)

I realize most of us are on a budget, but you would be better served to buy the underchassis headers. Granted they are expensive (~$500), but worth every penny. I think it makes the car a lot more streetable. The exhaust hangs way too low on the fenderwell headers and the tires rub unless you have really small tires on the front.

------------

REPLY by MopART@hm on 02-03-2000 05:43 PM:

Larry,

Dart is right on the money with everything he said. Oh, and if you're gonna trailer this car, be ready to hang those collectors on the end of the trailer unless you custom make some ramps or can jack the trailer WAY up there. Since you have to put such a small tire on the front it's gonna grab. And I surely wouldn't recommend these headers for a car that's gonna see ANY street use.

I *gave* a 6 month old set away..and the onlt reason why the gut got them was b/c his car was already hacked up.

But I must say ---- they look pretty nasty.

------------

REPLY by DUSTER340 on 02-03-2000 08:44 PM:

Had a friend who put a set on his '68' Barracuda and we changed the master cylinder about once a month[daily driver]. Heat in the engine compartment was so bad we had to install cool can to stop problems he was having with gas line getting to hot! Sure the starter was very easy to get off but he never had any trouble with it. No possible way to make the exhaust look good no matter how much money you spend. MOPAR or I walk!@#$

------------

REPLY by Christopher on 02-03-2000 08:47 PM:

I agree with all.I would never consider using Hooker's fenderwell tubes.You really weaken the uni-body structure cutting up the fenderwells and the bottom of the frame.I use a set that is avalible from Bob mazzolini racing in Riverside CA.1 tube from each side goes thru the fenderwell,and the hole is only big enough for the header flange to go thru.I'm considering a set of Stahl headers,but they are $900.00,so I'll have to debate that a bit more.I use 2' headers on both my mild 383 and 440 and they work fine.I have thought about a 1 7/8' tube size,but if the car went slower,I wouldn't be happy.

------------

REPLY by DartGT66 on 02-04-2000 01:13 AM:

I disagree with you all. I have used both underchassis and fenderwell headers in a BB A-body, and must truky say that the fenderwells are the way to go. I first bought the CPPA underchassis headers, I knew they were hard to install but handled it with a few extra dents. Had to use the convetional starter, because the MP mini starter didn't fit with them. Once in place, I had continuos trouble with primary to plug wire clearance problems, it ate plug wires almost daily. I tried to use different insulators between them, but no help, actually the boots touched the primaries, so it's no wonder. Changing the plugs was next to impossible, there was absolutely no room for a wrench in a RB A-body. After using them one year, I tossed them, and have never looked back. Performance wise they were a compromise, unequal length and very steep turns out of the heads + doglegs for the spark plugs. In our '73 Valiant we have the Hooker 2' super comps with a B-block; access to spark plugs is straight forward and working on the tec under the cylinder; no problems. The inner fenders have been removed and replaced with aluminum panels, and the Front end is supported by 2' rollcage tubes. The 'Pro-Parts' headers that Mazzolini sells are propably the best of the underchassis designs power wise, and the Schumachers easiest to install and perform well up to 4-500 hp. The CPPAs maybe support the same power, but are a real pain to install and live with. If you really want underchassis headers and have an ordinary street car, I suggest that you use the Schumachers. But if you have more power, on my opinion the fenderwells are the only reasonable possibility.

------------

REPLY by Christopher on 02-04-2000 06:54 PM:

No problem with any disagreeing at all from this end!! But you did bring up a point,actually two.I don't like the fact about the tire size limitation.I use a Moroso 7.10x15 and I know the tires of this size will hit the headers on a good turn.And I agree with running tubing from the front frame to the roll bar or cage if you cut the fenderwells.I feel this is a must if you do this.

------------

REPLY by dusterrcr on 02-05-2000 12:44 AM:

Seems like we have all had this discussion b/4.No I wouldnt put s/comps on a street car,no hooker doesent care about the problems that will cause.why? they were designed to produce HP in race cars. put ANY set of headers on ANY car and your asking for problems.I flashback to the chassis hdrs on my ol 71 charger,i could take the starter off,but i couldnt get it out without removing the header.Sort of like the guys that buy Holley carbs for the superior performance,then bitch about the ocassional leak theyre all born with. My hookers rub a little,I have to wrap my m/cyl with heat reflective tape.but they gave me 2 tenths off my time slip with no other changes. My suggestions for a street car,A set of Ma Mopars fine factory low restriction exhaust manifolds.---theyre bitch free!------later

------------

REPLY by Marc on 02-05-2000 01:00 AM:

I run the 2' CPPA's and must say there will probably be a different opinion or view from every car they are on! Mine eat starters. I'm intending on trying the new Mallory with the orbiting solenoid and a heat sheild.It also ATE plug boots. I solved this by squeezing rolled up wads of fireblanket between the primary tube and the plug boot.The collectors are big. My car sits LOW so it's a minor pain. I find the plugs fairly easy to change. Never had a problem. To fit the 2nd generation mini starter you must ding 1 header tube about 3/8' in. Most clearancing problems vary depending on where the engine is. Mine is mounted with Mancini elephant ears and seems to work pretty good. Anyone swapped to the 1 3/4' CPPA's or Schumachers?

I'll try ANYTHING - header swap,starter swap ..or?

------------

******************

TOPIC: Suggestions on heads, intake and cam for street 360?

by Knucklebuster_jr on 01-29-2000 10:32 PM

I found a short block 360, now I need heads and intake, and cam. But I'm not sure which ones..any suggestions would be appreciated greatly.

Andy

------------

REPLY by cudadude on 01-30-2000 12:13 AM:

question 1 is what kind of performance do you want out of your street 360. Try and find the last 4 issues of mopar muscle. they did a budget street build-up (2500.00) on a smog 360. They retained the stock smog heads and did a lot of work to them and got them flowing better than x heads. The end result netted them 390 hp. on the dyno. More power than the 360380 crate motor for a lot less money and a lot more work. One note, if you read these articles and decide to do your own heads be very carefull with them . They are easy to screw up. it is generaly better to take them and have them done unless you have a few sets to play with.

------------------

'MOPOWER' There Is No Substitute

*CUDADUDE*

------------

REPLY by cruzerjd on 01-30-2000 12:15 AM:

Hi, good find. I would use Mopar J heads, 2.02 intake, 1.60(?) exhaust, either a factory 4 bbl intake or an Edelbrock Performer depending on if you are on a budget or not. The Edelbrock is a close replica of the factory intake except for the plenum opening and the weight. If you are shooting for good mid range to upper rangs power, get the Performer RPM. As far as the cam, I am still wondering about that myself. I have a 318 with a 600 cfm 4 barrel holley on a cast iron manifold and plan on using the 1.88 intake heads (318's have a smaller bore, so I do not want the 2.02 heads), and may be upgrading the cam soon as well. From what I have heard, the MP 340 cam is a good selection and may be what I run. What exactly are you putting it all in anyway?. cruzerjd

------------

REPLY by Knucklebuster_jr on 01-30-2000 08:18 AM:

Yeah, I'm still on a budget, but I'm getting that short block for $30!! So basically you're saying I can take any head and make it flow like crazy with lots of work? This will go in my '88 Dakota. I hope it'll fit with headers!

[This message has been edited by Knucklebuster_jr (edited January 30, 2000).]

------------

REPLY by Speedy#1 on 01-30-2000 09:03 AM:

I thought that mopar muscle was a vary good build up especially for the back yard machnic .Any time you can get 79 smog heads to flow better than X heads you got my attention .I don't know if you guy's priced X or J heads lately but you can rebuild the hole head for what you would pay for just a core.plus all the tinkering was just new valves ,gasket matching,and some blending.I don't consider that to be a lot of work unless some one else is doing the work for you.plus most of the gains were from the valve desighn and a 30*valve seat.but after reading that my thought's on cylinder heads went to sh----t .

------------

REPLY by MopART@hm on 01-30-2000 10:54 AM:

knucklebuster_jr,

What year model is the 360?

------------

REPLY by Knucklebuster_jr on 01-30-2000 01:12 PM:

I don't know what year. I know it's pre-magnum, if that helps. And does anyone know, is there any one block better than another?

------------

REPLY by 340king on 01-30-2000 08:11 PM:

You can determine the uear of casting by inspecting the driver's side of the block. There should be a cast date on it. You can also look just under the driver's side deck on the front of the block. There should be a set of numbers stamped there also. These numbers are coded, but if you post them someone here is sure to decode them for you.

The pre-74 blocks are generally considered to be better. They were supposedly cast thicker. If you have any doubts, sonic test the block, checking for thickness and core shift.

------------

REPLY by 440Ramcharger on 01-31-2000 08:50 AM:

I would definitely check out the Weiand 8007 dual plane intake. I have this on a 340

4 speed '75 Duster and on a '70 Duster. Engines were set up in the following manner.

'75 '69 340 x heads 9.0:1 MP 284 / .484' cam, TQuad runs in the 14's with 225 wide (skinny) back tires.

'70 '70 318 block with J heads 360 crank machined to fit & rotating mass balanced.